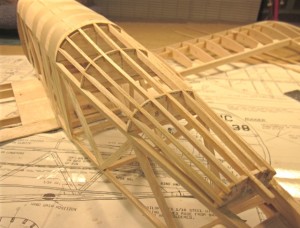

- There’s a lot going on here. All the top/rear fuselage deck formers are in place. In this kit they started life as printed parts outlines. First the entire former is cut from the balsa sheet and then the various slots or openings for the stringers are cut in on the marked locations. (It’s possible for those locations to be marked wrong..an issue I’ll discuss later, in another context). This time they were right. These stringers are 1/8″ x 3/16″ balsa strips supplied a bit over length. I fitted each of them in turn, checking that they lie straight and trimming any notches that don’t fit just right if necessary. Here I am using thin (fast) cyanoacrylate as my adhesive.

All the top rear deck stringers are in place here. Notice that they fit against the back edge of the front deck/sheet covering and stop at the last former before the tail post. There's a reason for this that we'll talk about later.

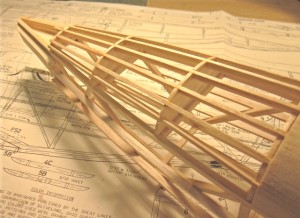

This is a view of the same top deck stringers in place looking toward the tail.

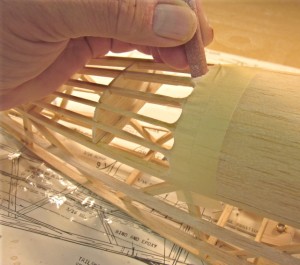

This is a step the FlyLine plans don’t mention. Where the stringers meet the rear edge of the balsa sheet top deck there is a squared-off transition from balsa sheet structure to open (fabric covered) structure. It’s possible to give this part of the structure a much more finished appearance by adding what amount to gussets between the stringers. Here I have fitted scraps of 3/32″ balsa sheet between each pair of stringers.

This is a step the FlyLine plans don’t mention. Where the stringers meet the rear edge of the balsa sheet top deck there is a squared-off transition from balsa sheet structure to open (fabric covered) structure. It’s possible to give this part of the structure a much more finished appearance by adding what amount to gussets between the stringers. Here I have fitted scraps of 3/32″ balsa sheet between each pair of stringers.

I used a sanding block to smooth the gusset/filler pieces flush with the surface of the stringers and the balsa sheet deck.

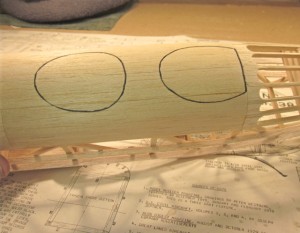

The custom sanding tool is just a piece of 100 grit production aper wrapped tightly around a scrap of metal tube that happened to fit the opening I wanted to work with. For jobs like this it's worth digging around the shop for a few minutes to find a scrap of material that will fit just right. Notice that I have marked off the line defined by the front edge of each radius cut-out with a strip of masking tape, which I'll remove later.

This is one of the most important of the "expert" techniques you can learn about built up, fabric covered models. The purpose of the stringers is to hold the fabric covering in a specific contoured shape. The purpose of the formers is to hold the stringers where they belong - NOT to bump against the inside surface of the covering and make awkward lumps. Leave the formers intact at each end of a "bay" of covering and scallop them out everywhere else. Just as with the gussets, use a conveniently sized scrap of dowel or tube to create exactly the sanding block you need.

With the formers cut out and the tops of all the stringers sanded flush, I gave the top decking another sanding to remove any lingering bumps or high spots and then marked the cockpit openings using a pattern made by tracing the outlines off the top fuselage view on the plan and marking the cutting lines onto the balsa sheet.

Bob,

This build is looking good. Gussets and scallops, I like it!